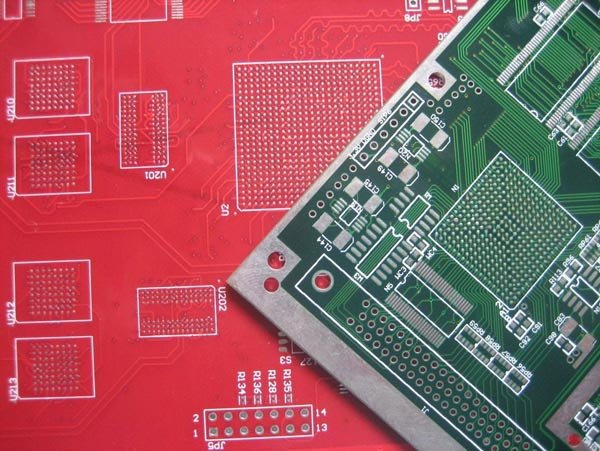

WHY CHOOSE APC AS YOUR PCB ASSEMBLY MANUFACTURER?

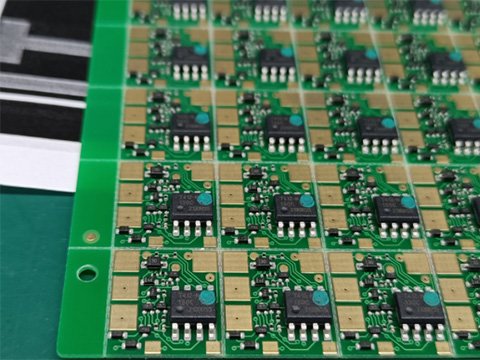

Strict Quality Control

We are a PCB assembly factory in China since 2004. We focus on middle and high-end complete turnkey PCB assembly. 99.9% pass rate.

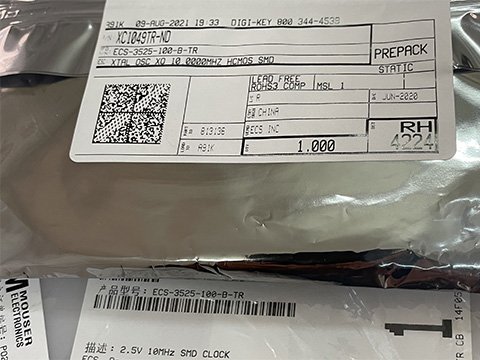

Original Parts Sourcing

We source the electronic components from big trader or original manufacturers. Distributors such as Future, Avnet, Arrow, Master, Digi Key, Mouser and so on.

Solder Paste Storage

We pay high attention to the management of solder paste and we have introduced a constant temperature management alarm system.

Parts Pre-baking

In order to improve the soldering reliability, we have dedicated oven for PCB & component pre-baking.

Inspection

We do visual inspection, AOI inspection, x-ray inspection. QC strictly enforces the standards: IPC II and IPC III.

Programming and FCT

We provide programming and FCT (function test) services to ensure that every product you receive is qualified.

Component Storage

We attach great importance to component storage. Such as temperature and humidity control and first-in-first-out mechanism.

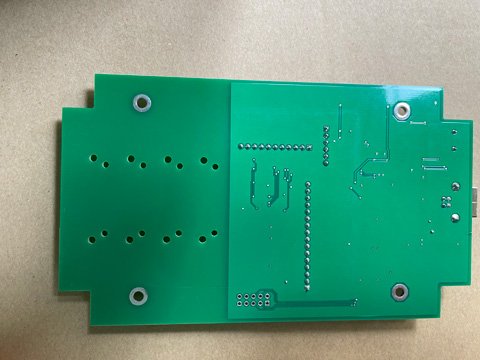

Reliable Packaging

We provide customized packaging solution to ensure your boards arrive you safely.

On-Time Delivery

We implement MES electronic information board to supervise the PMC production plan so we can deliver the product timely.